Animation of Pulleys and Belt

Drive System

Introduction

This

animation provides learning of drive speed ratios and the dynamics of how the

driven load affects the driving belt's sag.

Its design algorithms also show how to maintain digital integrity of the

links of the belt without slippage on the pulleys.

Figures

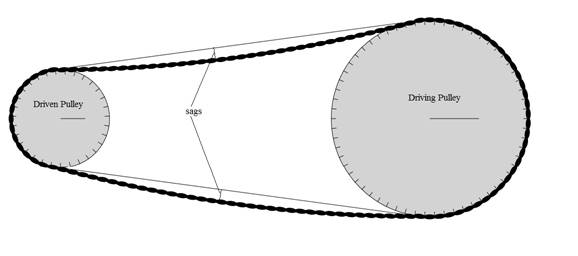

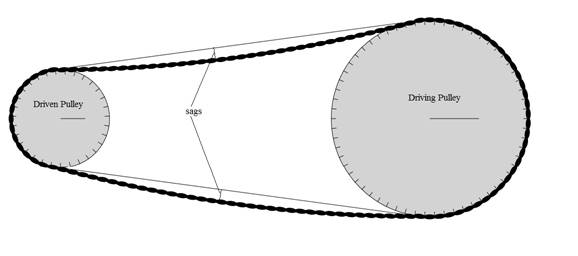

Figure 1.

Pulleys with belt under motionless conditions.

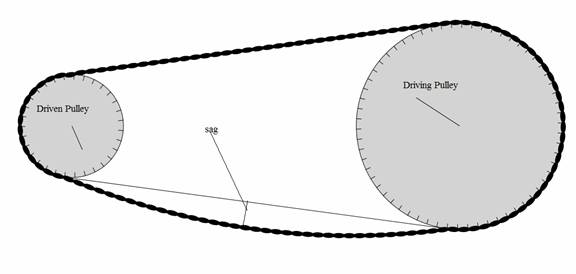

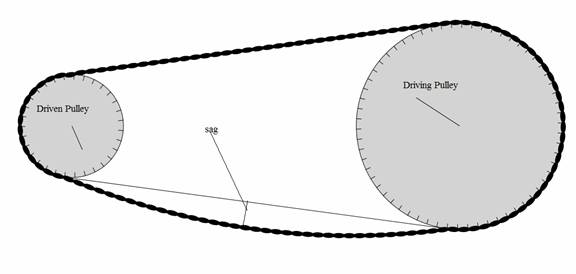

Figure 2.

Pulleys with belt under driving conditions. Note the lack of sag on the belt's top span

and the doubling of sag on the belt's bottom span.

Math

1. Initial Layout:

We will make integer numbers of equal length links on both free spans and on

both pulleys by adjusting start angles on the left and right pulleys and by

adjusting the horizontal distance between the pulleys. In order to get integer numbers of links on

the pulleys we use the following algorithm:

|

|

|

(1.1)

|

where l is the

link length, ab is the radius of the big pulley and as is

the radius of the small pulley.

Then we solve the equations (1.1)

for θb and θs:

|

|

|

(1.2)

|

The math for the span between pulleys involves a quadratic

equation:

|

|

|

(1.3)

|

where δxp is the horizontal distance

from the center of the small pulley to the center of the big pulley and nsp

is the previously chosen number of links in the free spans.

2. Motion:

Here the idea is to save a copy of the stationary belt and

then have the moving belt segment morph gradually

into the stationary segment as it arrives there. In order to achieve this, it

is simpler to save several iterations of each link position in an array so that

the link can be stepped sequentially to an exact and repetitive position.

The code to move a single segment along the belt path is

shown below where i represents the integral link step number, n is the total

number of links, m is the number of the current link being advanced, j is the

discrete step number and there are njs steps for each full link advancement.

//i is the current value of advancement;

int k= i % n;

//advance all ellipses by len/njs from their stored positions

for(int m=0;m<n;m++)

{//m is the link number being advanced

int kmMod=(k+m) % n;

ellipse

em=eList[m];

int index=njs*kmMod+j % njs;//2D data array, pA, index

em.x=pA[index][0];

em.y=pA[index][1];

em.angle=pA[index][2];

}

j++;

if(j % njs==0) i++;